Replica of a Fokker Dr.1 Triplane in the Deutsches Museum, Munich. A very agile airplane, but not very fast, so by the end of the war, no longer capable of operating inside opponents’ OODA loops.

If you look down through the sweep of history, you might see two broad trends in the concept we call “agility” or “maneuver.” In the military, including the martial arts, people have known that certain practices could disorient opponents, making the physical act of combat much easier to win. Among these were deception, ambiguity (the “fog of war”), the ability to operate at a rapid tempo, and especially a rapid shift between what the opponent expects and what they experience. The oldest known documentation of these ideas comes from the Sun Tzu text, fragments of which date back to 300 BCE, and they flow like a stream through later Chinese commentators, the Japanese samurai, various schools of the martial arts, the campaigns of Genghis Khan, the German “blitzkrieg,” and on to our day via the works of John Boyd and the US Marine Corps doctrine of maneuver warfare.

Sometime after World War II, in Japan, they jumped the military track and into, of all things, automobile manufacturing. Known today as “lean manufacturing,” the philosophy and set of practices that began as the Toyota Production System broke longstanding tradeoffs between cost, delivery time, and quality. Before the TPS, and in US auto manufacturing up until the 1990s, higher quality meant higher costs. The TPS showed that it was possible to build better cars cheaper.

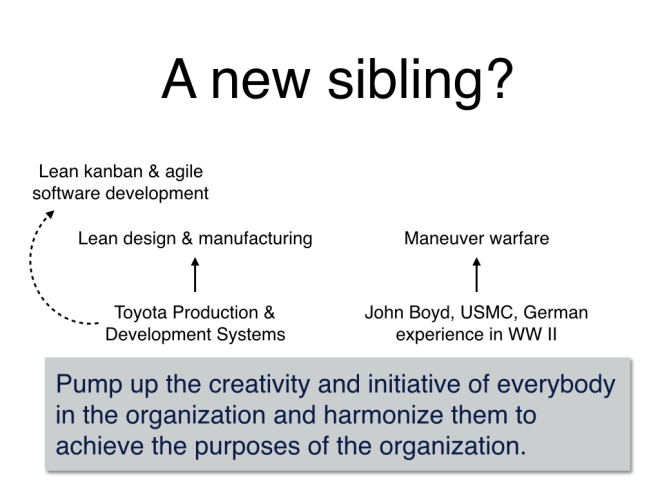

Why is the TPS another manifestation of the principles that underlie maneuver warfare? For one thing, they both accord a central role to time. Sun Tzu wrote that quickness is the essence of war. Similarly, the TPS stresses the continuous reduction in the time between when a customer places an order and when they receive the vehicle. And as this chart from my keynote illustrates, they both rest on a philosophy that stresses human creativity and initiative:

Both maneuver warfare and lean are mature concepts. One could argue that all the elements that define maneuver warfare were identified and in place no later than the early 1940s and might even make a case for 1936, when the German Army issued its doctrine for command of troops, the Truppenführung. If you’re interested in the details, Martin van Creveld provides an extensive analysis of the Truppenführung in his book Fighting Power. These concepts were refined by John Boyd, Bill Lind, and a group of young officers in the Marine Corps beginning in the early 1980s and reached what is essentially their current state with the publication of Marine Corps Doctrine Publication 1, Warfighting in 1989.

Similarly, Taiichi Ohno, one of the prime creators of the system at Toyota, maintained in his book Toyota Production System that the basics of the system were in place by 1973. In 1979, in response to claims that the Japanese were dumping cars at below cost (nobody could sell a car that good for so little!), MIT began the International Motor Vehicle Program, which documented the system and compiled data that demonstrated its effectiveness. Their results were presented in a number of articles principally in the Harvard Business Review and Sloan Management Review and popularized in the 1990 book, The Machine that Changed the World. Two of the authors of that work continued to develop the ideas into a more general theory of lean and published them in Lean Thinking (1996). At about the same time, Allen Ward and his colleagues at the University of Michigan were researching the Toyota Vehicle Development System, which applies the same underlying principles but in quite novel ways. This may be evident from the subtitle of their 1995 paper, “How Delaying Decisions Can Make Better Cars Faster.”

It’s been 20 years since anything significant developed in the world of maneuver, agile, and lean. My 2004 book, Certain to Win, looked more at the relationships between maneuver and lean. It was the first to point out the common foundation of maneuver and lean, particularly the “human” factors that underly both (by “pumping up creativity …”). It noted that in business, the military concept of grand strategy reduces to “ordinary” strategy. It offered an interpretation of the maneuver concept of cheng / chi that, by focusing on the customer, not the competitor, works for business, too. Good foundational stuff, but it wasn’t written to divert the lean / maneuver pattern into a new field of application.

So it’s about time that the maneuver stream found a new channel, that it broke out of the worlds of manufacturing and war and over into what we might call “white collar” occupations. From the quality and intensity of the discussions at LKCE15, building on what I first observed at Lean Software & Systems 2011 in Long Beach, we may be seeing the power of these ideas manifesting in an entirely new area:

Lean kanban incorporates many of the practices associated with classical maneuver / lean theory: managing flow, limiting work-in-process inventory (which can hide problems and distort orientation), and employing an hypothesis-test methodology for learning. According to the web site of one of its founders (and a keynote speaker at this conference), David Anderson, it also “encourages acts of leadership at all levels.” Depending on how they implement this idea, it could be in harmony with “Pump up the creativity and initiative of everybody …” Because this concept is the real foundation of classical lean and maneuver, I’d need to know more before pronouncing a final judgment. Looks promising, though.

For more information, check out the conference’s sponsors — there are links down at the bottom of the conference’s home page.

I’ve done theme that mobile & lean converge with agility.

In addition to sponsoring Boyd’s briefings at IBM, I was also blamed for online computer conferencing (precursor to social media) on the internal network (larger than arpanet/internet from just about the beginning until sometime in mid-80s) in the late 70s and early 80s … where we had a lot of agility related discussions.

In the early 80s there was Washington Post article calling for 100% unearned profit tax on the US auto industry … import quotas were supposedly to provide US auto industry with significant profits (reduced competition allowing significant price increases) that would be used to remake the industry; however they just pocketed the profits and continued business as usual.

In 1990, the US auto industry had the C4 taskforce to look at completely remaking themselves and because the were planning on heavily leveraging technology, major technology vendors were invited to send representatives. In the meatings they had detailed descriptions about what the foreign makers were doing and what US makers needed to change. One of the detailed descriptions was the auto industry had been taking 7-8yrs to go from start to rolling off the line (and were typically running two efforts in parallel offset by a couple years … so something new was coming out every 3-4 years instead of 7-8 years). Foreign imports had cut the process in half (3-4yrs) and were in the process of cutting it in half again (18-24months). Foreign imports could respond to changing buying habits or changing technology much more quickly than US makers. Offline I would chide my IBM “mainframe” brethren (that were attending) how could they expect to help (since they had similar schedule, 7-8yr product cycle, with two efforts running in parallel offset by a couple years)? Silicon Valley chip products were on path towards 18-24month.

As an aside, in the early-to-mid 80s, I had a project I called HSDT (high-speed data transport) and was working with director of NSF on connecting the NSF supercomputer centers. Some of the stuff was being built on the other side of the pacific and would have to visit periodically (one of the vendors was Matsushita and they couldn’t resist showing off some of the stuff they were doing for Toyota). As an aside, as regional networks tie into the NSF supercomputer centers, it morphs into the NSFNET backbone … precursor to modern Internet.